Impact of Temperature Variations on the Performance of Piezoelectric Ceramics in Level Switches and Engineering Countermeasures

In the field of industrial automation, piezoelectric ceramics, as a typical class of functional ceramic materials, are widely used in medical imaging, ultrasonic transducers, acoustic sensors, and precision actuators due to their unique electromechanical conversion properties. In the field of level measurement and control, especially in vibrating level switches, piezoelectric ceramics also play an irreplaceable and critical role.

For vibrating level switches, piezoelectric ceramics serve not only as the excitation source for vibration signals but also as the sensing unit for vibration status. Their performance stability directly determines the reliability, response consistency, and long-term operational life of level switches under complex working conditions. Once the performance of piezoelectric ceramics degrades, minor consequences may include false switching, while severe cases may lead to failure of equipment interlock systems, posing potential risks to production safety.

Multiple Factors Affect Piezoelectric Ceramic Performance, with Temperature Being the Most Critical Variable

In practical industrial applications, the operating condition of piezoelectric ceramics is not isolated but influenced by multiple external factors, including:

- Process temperature and ambient temperature

- Environmental humidity and condensation

- Mechanical stress applied during assembly

- Long-term vibration and thermal cycling loads

Among these factors, temperature variation has the most significant impact on the performance of piezoelectric ceramics and is also one of the most difficult variables to avoid in engineering design. Especially under conditions of high temperature, frequent temperature fluctuations, or thermal shock, piezoelectric ceramics are more prone to performance degradation or even irreversible damage.

From the perspective of material microstructure and physical mechanisms, temperature variations mainly pose the following risks to piezoelectric ceramics used in level switches.

I. Thermal Energy-Induced Domain Structure Changes Leading to Performance Aging

Piezoelectric ceramics are composed of a large number of domain structures. In addition to stable 180° domains, they also contain a certain proportion of metastable non-180° domains. These metastable domains exhibit high structural variability under external energy input.

When ambient or process temperature rises, thermal energy accumulates within the material, causing some metastable domains to reorient or undergo structural adjustments, which in turn leads to localized depolarization. Although this change may not be obvious in the short term, over time it gradually manifests as:

- Reduced driving efficiency

- Decreased vibration amplitude

- Deteriorated signal stability

From a macroscopic perspective, this process is reflected as “gradual aging” of the electrical properties of piezoelectric ceramics, ultimately affecting the detection reliability of level switches.

II. Risk of Irreversible Depolarization Caused by Sudden Temperature Changes

Compared with gradual temperature increases, sudden temperature changes are far more destructive to piezoelectric ceramics. When a piezoelectric element experiences drastic temperature differences within a short period, internal thermal stress and thermal energy concentrate rapidly, easily triggering large-scale domain reorientation.

Once this reorientation exceeds the recoverable threshold of the material, irreversible depolarization occurs, resulting in permanent degradation of the electromechanical coupling performance of the piezoelectric ceramic. Such damage is usually impossible to fully restore through re-poling and can only be resolved by replacing the component.

In practical applications, this risk commonly occurs in the following scenarios:

- Frequent startup and shutdown of high-temperature process equipment

- Level switches directly exposed to high-temperature media

- Cold instruments suddenly installed into high-temperature operating environments

III. Practical Challenges of Hot Replacement Under Continuous High-Temperature Operation

In continuous production systems, shutdown for maintenance is often not feasible due to process requirements. When a level switch fails and must be replaced while the equipment remains in high-temperature operation, the newly installed level switch is immediately exposed to hot process media.

Under such conditions, the piezoelectric ceramic transitions rapidly from ambient temperature to high temperature and is highly susceptible to thermal shock. Without appropriate thermal buffering or isolation measures, depolarization may occur before thermal equilibrium is established, directly affecting normal operation and even resulting in “immediate failure after installation.”

Engineering Countermeasures for Temperature Effects

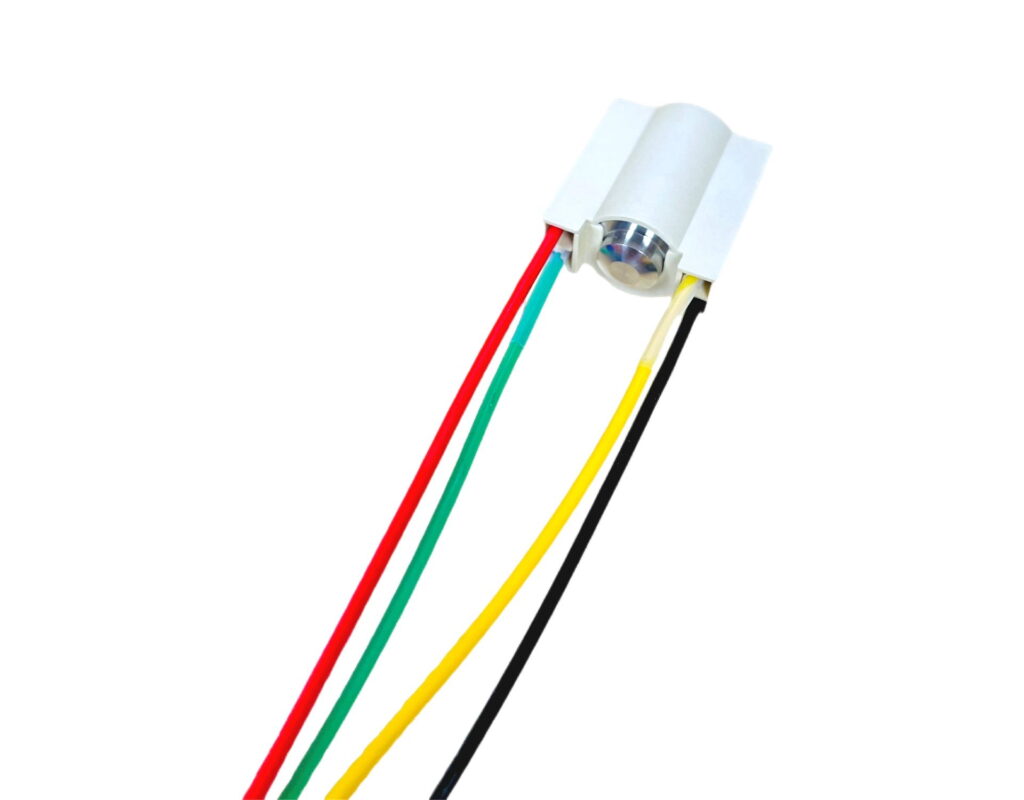

In response to the widespread challenges of high temperature, frequent temperature fluctuations, and pronounced thermal shock in industrial environments, Shenzhen Jiwei Automations Ltd has systematically enhanced the temperature adaptability of piezoelectric ceramics in vibrating level switches through both optimized structural design and careful material selection. During development, full consideration is given to potential depolarization, performance degradation, and long-term stability issues of piezoelectric ceramics under high-temperature conditions, and these risks are effectively controlled through engineering measures.

In terms of structural design, thermal buffering and isolation mechanisms are introduced to reasonably control the rate of heat transfer from the process to the piezoelectric elements, preventing excessively rapid temperature rise under high-temperature or sudden temperature-change conditions and thereby reducing thermal stress on the domain structure. In material selection, priority is given to piezoelectric ceramics with higher temperature stability and superior heat resistance, enhancing reliability from the intrinsic material properties.

Through the coordinated optimization of design and materials, Jiwei vibrating level switches can stably withstand process temperatures of up to 400 °C in practical applications. Even in extreme industrial environments such as metallurgy, chemical processing, and energy industries—characterized by high temperatures and continuous operation—the switches maintain excellent vibration characteristics and switching reliability, providing long-term and stable level detection and safety assurance for on-site equipment.

I. Structural and Assembly Design: Introduction of Thermal Buffering and Isolation Mechanisms

During the structural design phase of the piezoelectric assembly in level switches, Jiwei fully considers adverse operating conditions such as high temperature, temperature fluctuations, and thermal shock, and incorporates dedicated thermal buffering and isolation structures between the piezoelectric elements and the process media.

The core objectives of this design are to:

- Reduce the instantaneous heat transfer rate from the process to the piezoelectric elements

- Prevent rapid surface temperature rise of piezoelectric ceramics

- Establish a smoother thermal transition process for the piezoelectric elements

Even when the process temperature changes abruptly, this buffering structure effectively suppresses the temperature rise rate of the piezoelectric elements, thereby reducing the likelihood of thermal disturbance to domain structures and significantly improving the long-term stability of piezoelectric ceramics under complex working conditions.

II. Material Selection: Preference for High-Temperature-Stable Piezoelectric Materials

In terms of material selection, Jiwei Automations prioritizes piezoelectric ceramics with superior temperature stability and higher depolarization thresholds, enhancing product heat resistance at the material property level.

By systematically evaluating the performance of different piezoelectric materials under high-temperature and thermal cycling conditions, Jiwei ensures that selected materials maintain good electromechanical conversion characteristics and long-term consistency within the typical operating temperature range of level switches.

This material-oriented strategy, combined with structural thermal buffering design, provides level switches with greater safety margins and reliability in high-temperature and temperature-fluctuating environments.

Conclusion

In vibrating level switch applications, piezoelectric ceramics are not merely electronic components but core functional elements that determine equipment reliability and service life. Temperature variations—especially high temperatures and sudden temperature changes—have a significant and unavoidable impact on piezoelectric ceramic performance.

Only by addressing temperature risks at the engineering design stage through appropriate structural design and material selection can stable operation of level switches in complex industrial environments be truly achieved. Based on this engineering philosophy, Shenzhen Jiwei Automations Ltd continues to optimize product design, providing users with more reliable and adaptable level detection solutions.