Polymer Material Aging: From Formation to Controlled Lifespan

Many people think material aging happens years later. In fact, polymer materials start changing from the moment they are molded. Common aging phenomena observed in engineering practice include yellowing, reduced mechanical performance, surface roughness or cracking, mold growth, and unstable electronic properties. Some attribute this to process instability, others to chain breakage—both are partially correct but incomplete. Material Aging

This article systematically explains, from an engineering perspective, why polymers age, why aging validation is essential, how to monitor and test, strategies to extend lifespan, and common pitfalls to avoid.

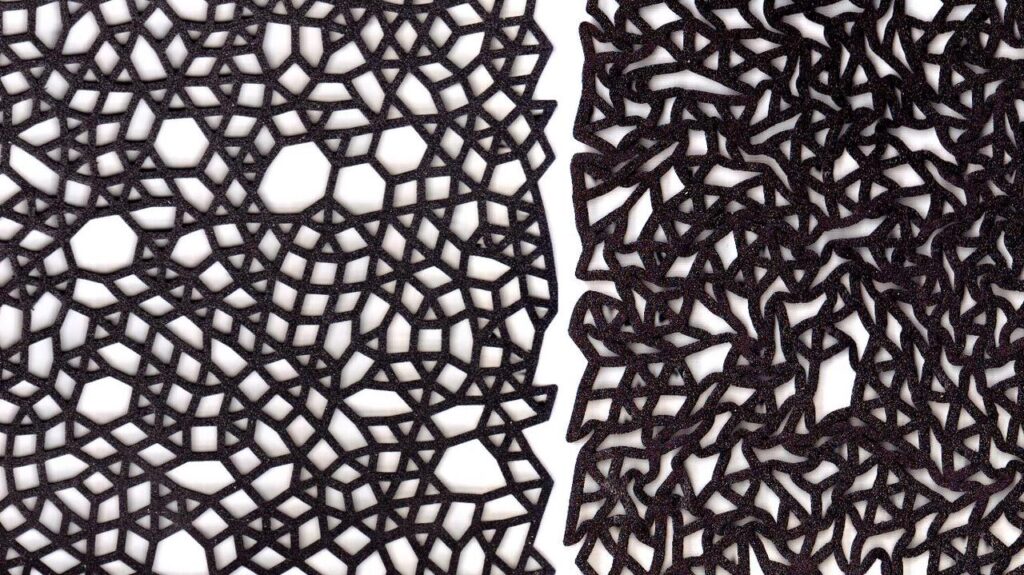

Aging Begins at Material Formation

Polymers are typical non-equilibrium systems: chemical bonds vary in strength, chain segments differ in mobility, and crystalline and amorphous regions coexist. During use, input of heat, light, oxygen, moisture, and stress triggers molecular rearrangement, chain breakage, oxidation, or crosslinking reactions. Material Aging

In short, aging is the material’s spontaneous evolution toward a more stable state. Manifestations can include yellowing, embrittlement, or microcracks. Observed features vary depending on perspective. In engineering, aging is inevitable; the key is to delay and control it.

Defining Aging Evaluation Criteria

Critical aging indicators differ by application:

- Automotive seals: air/water tightness, elongation, surface cracking

- Semiconductor packaging: electrical performance and reliability

- Outdoor cables: UV and weather resistance

Evaluation should be based on material characteristics, customer requirements, and service environment, rather than blindly copying others’ standards.

Importance of Aging Validation

New engineers may ask, “The material seems fine; why test for aging?”

Aging validation is not superfluous—it is core to engineering risk management. Material Aging

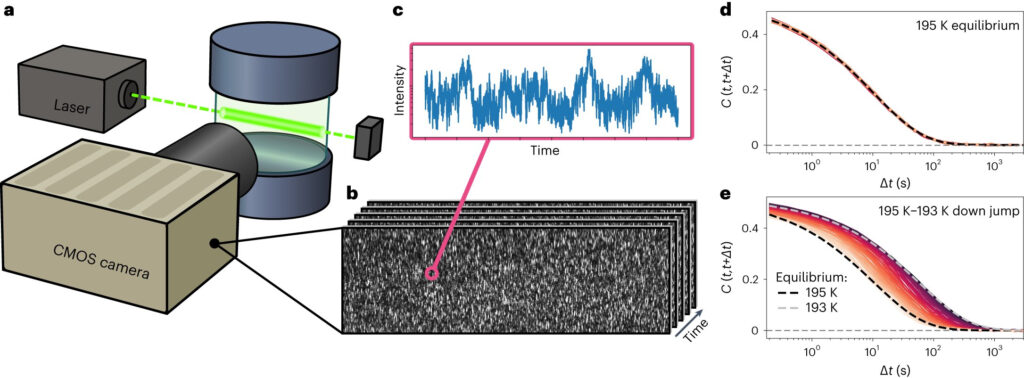

- Scientific perspective: Polymers are non-equilibrium systems from formation. Under light, heat, oxygen, moisture, and stress, irreversible molecular rearrangements, chain breakage, or crosslinking occur. Aging tests compress years of changes into weeks or months to assess lifespan in advance.

- Engineering perspective: Main purposes include:

- Predicting lifespan and performance decay: Accelerated and real-time tests establish performance-time curves for lifetime prediction, supporting “usable for X years” claims.

- Screening formulations, processes, and protective measures: The effectiveness of antioxidants, stabilizers, and fillers often becomes clear only under aging conditions, helping remove potential failure risks.

- Verifying application scenarios: Simulated aging evaluates reliability and safety margins under different environmental conditions such as temperature, humidity, UV intensity, and mechanical stress.

In summary, aging tests aim to determine when and how performance changes occur, enabling proactive lifespan design rather than merely proving the material will degrade.

Aging Validation Methods

Focus on trends from molecular to structural to performance levels rather than single-point data:

- Chemical:

- Chain breakage or crosslinking: GPC for molecular weight and distribution

- Oxidation or hydrolysis: FTIR monitoring of new carbonyl or hydroxyl peaks

- Small molecule degradation: GC-MS to detect volatiles or byproducts

- Thermal:

- Tg (glass transition temperature) reflects chain mobility

- Crystallinity changes: early aging often occurs in amorphous regions

- Mechanical:

- Strength, elongation, modulus

- Fatigue and creep (essential for long-term stress)

- Surface/Interface:

- Color difference ΔE for visible changes

- Microcracks or crazing (SEM/AFM)

- Surface chemistry (XPS/FTIR for oxidation layers or functional groups)

- Electrical/Optical:

- Insulation, resistivity

- Transmittance, haze (films)

Key: select indicators that reflect the aging mechanism and monitor their trends over time and environment.

Accelerated Aging vs. Real Conditions

Common acceleration methods include: thermal (heating + Arrhenius extrapolation), light (UV exposure), humidity cycles (temperature/humidity alternation), and mechanical cycling (bending, stretching, vibration).

The mechanism of acceleration must match actual aging conditions. For example, if high temperature drives crosslinking while room temperature drives slow oxidation, purely thermal acceleration can lead to inaccurate extrapolation. Correct approach: use acceleration for screening and design, then calibrate the model with limited real samples.

Engineering Lifespan Extension Strategies

- Chemical protection: antioxidants, UV absorbers, light stabilizers, hydrolysis stabilizers; monitor consumption rate and side reactions.

- Physical isolation: coatings, barriers, or shading to reduce O₂, moisture, and light ingress; e.g., carbon black in outdoor cables improves UV stability.

- Structural optimization: reserve safety margins, protective positions for key materials, and design replaceable/ redundant structures.

- Process control: reduce residual stress, fully degas, control humidity and temperature, ensure clean raw materials and process consistency.

- Maintenance: online sensors and periodic inspections allow monitoring and early warning.

Common Pitfalls

- Surface changes ≠ total failure: yellowing or cracking does not indicate mechanical collapse but may accelerate bulk aging; treat as early warning.

- Blind high-temperature acceleration: can trigger alternative chemical pathways; verify mechanism via FTIR/GC-MS.

- Single-indicator assessment: color stability does not mean molecular weight is unchanged; no surface cracks do not imply mechanical performance remains; combine chemical, thermal, mechanical, and surface indicators.

Proactive Aging Management

Aging is not a sign of material failure but an inherent property. True engineering capability lies in making aging measurable, controllable, and designable: turning “material is aging again” into “under X conditions, Y indicator will reach critical value in Z time.” By defining X/Y/Z, engineers can move from reactive management to predictable reliability engineering, achieving controlled lifespan and predictable performance.