-

Jiwei Modular Circuit Protection Design for Reliable Vibrating Level Switches

Modular circuit protection with potting ensures safe, stable, and long-term operation of reliable vibrating level switches in harsh conditions.

-

Do Thermal Insulation and Jackets Affect Magnetic Level Gauges?

Insulation, vacuum jackets, and pipe materials in magnetic level gauges: only ferromagnetic materials affect magnetic field transmission.

-

Comprehensive Guide to Common Radar Level Meter Fault Troubleshooting

Learn how to troubleshoot radar level meters in chemical, energy, metallurgical, environmental, and pulp & paper industries.

-

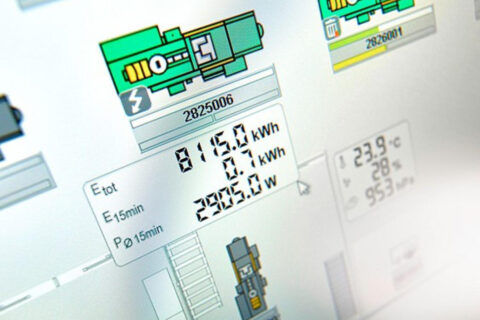

Differences Between PROFIBUS and PROFINET in Industrial Automation

PROFIBUS vs PROFINET: Key differences in industrial automation, communication architecture, and system capabilities.

-

One of China’s Representative Level Meter Manufacturers: Jiwei Automation’s Technical Strength and Engineering Practice

In industrial automation systems, level and point level measurement occupies a position that is “low-profile yet critical.” Unlike control systems, wh…

-

Analysis of Field-Level Controller in Automation Projects

Field-level controllers (PLC) ensure control reliability, data integrity, and traceable operations in automation systems.

-

Working Principle and Application Analysis of Flameproof Level Switches

Flameproof level switches provide safe, stable level detection in flammable gas and dust environments for oil, chemical, and silo applications.

-

Why JWrada® Radar Level Transmitters Are More Than Just “Radar”

JWrada® 80GHz FMCW radar level transmitters are for stable measurement in high-temperature, dusty, steamy, and hazardous applications.

-

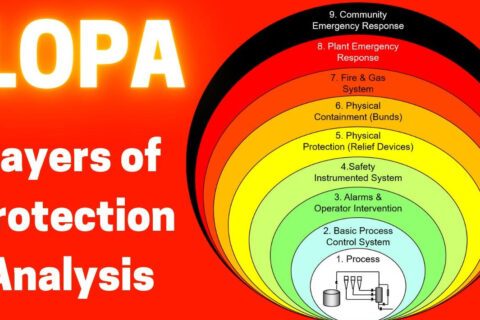

HAZOP, LOPA & SIL: Understanding Their Roles in Process Safety Management

Learn the differences and roles of HAZOP, LOPA, and SIL in process safety: from scenario identification and risk assessment to instrument reliability.

-

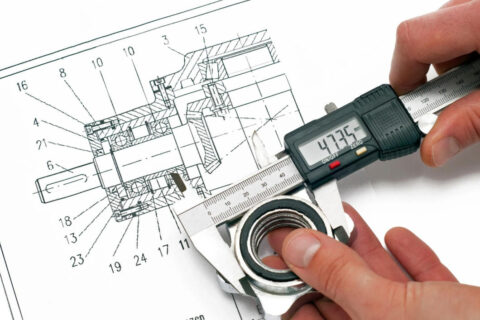

Tolerance and Accuracy: How to Distinguish and Balance in Mechanical Design and Manufacturing

Learn how to distinguish tolerance and accuracy in mechanical design, choose the right grades, and balance precision.