Interlocking vs Sequential Control: 1-Minute Guide

In the fields of industrial automation, mechanical engineering, and system design, Interlocking and Sequential Control are two critical concepts. Although they are often confused in everyday discussions and sometimes used interchangeably in documentation or schematics, they differ fundamentally in function, design principles, and application scenarios. Correct understanding and application of interlocking and sequential control can significantly enhance system safety, reliability, production efficiency, and equipment lifespan.

1. Basic Definitions of Interlocking and Sequential Control

Interlocking

Interlocking is a safety control measure designed to prevent operations under unsafe or inappropriate conditions. Through interlock design, a system can block device operation until specific conditions are met, ensuring safety or preventing equipment damage.

Example: In elevator systems, the interlock prevents the elevator from moving if the door is not fully closed. In high-pressure chemical equipment, the pump cannot start if a valve is not correctly positioned.

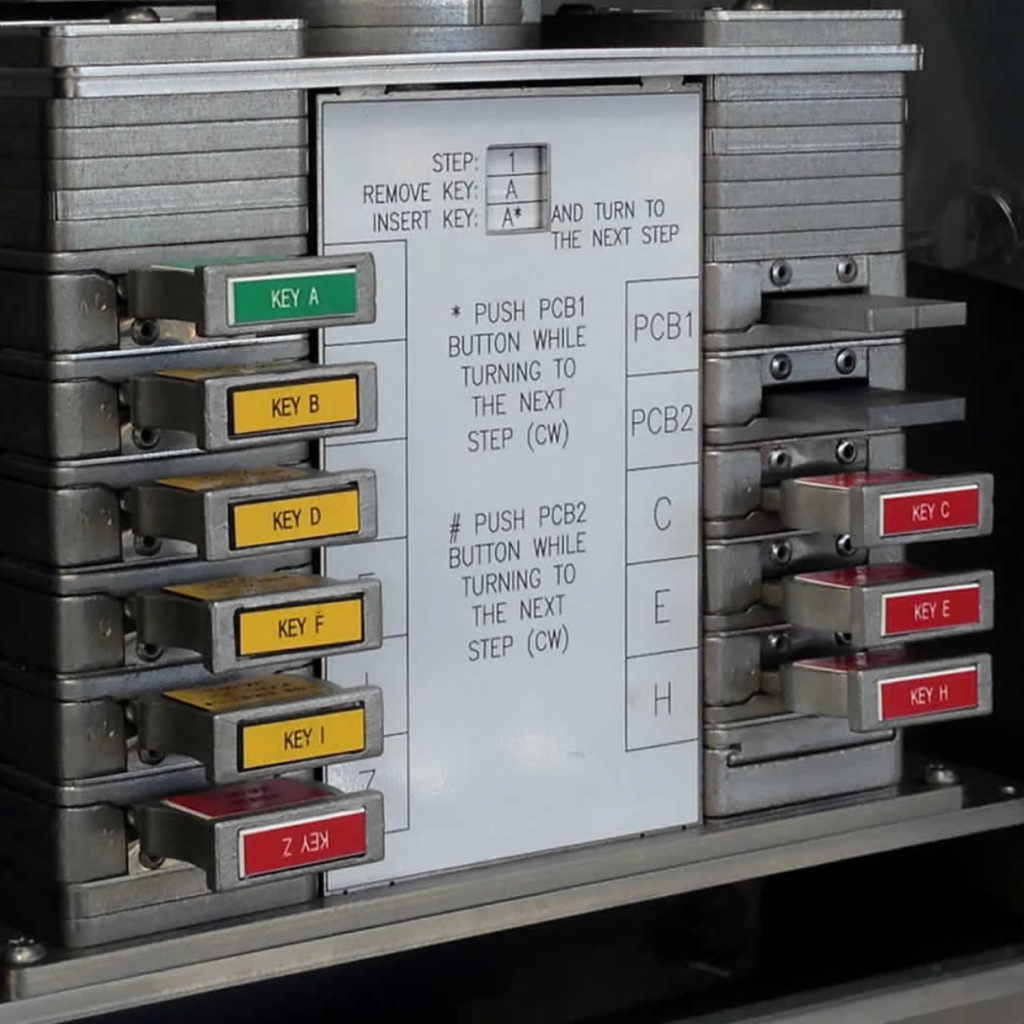

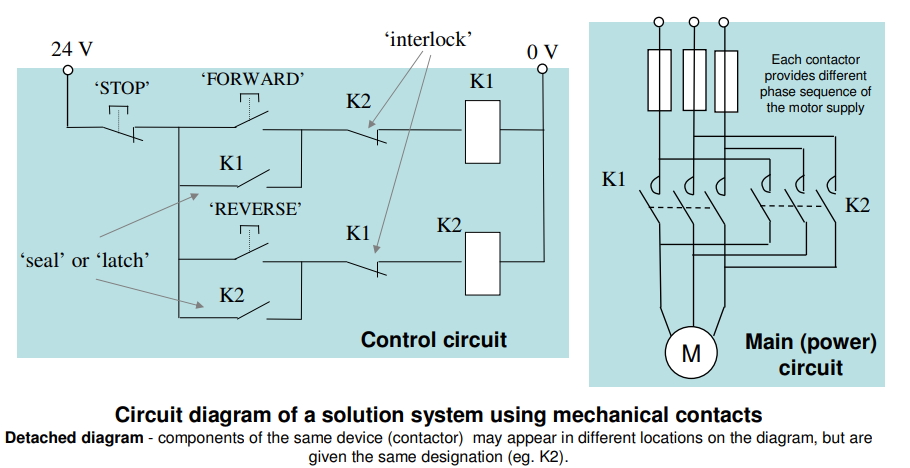

Interlocks can be implemented through hardware (mechanical limit switches, relays) or software logic, emphasizing condition constraints and safe operation sequences.

Sequential Control

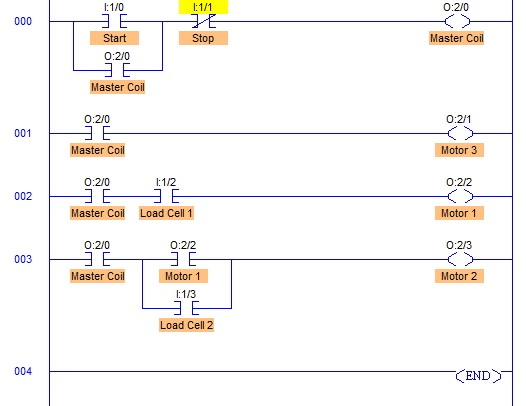

Sequential control refers to a series of devices or operations that depend on each other in a specific order, forming a continuous operation chain. Its main purpose is to ensure smooth workflow and operational continuity.

Example: On an assembly line, conveyor B only starts after conveyor A completes its task. In logistics systems, downstream sorting machines activate only after upstream conveyors finish running.

Sequential control emphasizes temporal order and operational dependency, not necessarily safety constraints, but is critical for process efficiency.

2. Key Differences Between Interlocking and Sequential Control

Function and Purpose

- Interlocking ensures safety and prevents incorrect operations by restricting actions until conditions are met, reducing the risk of accidents or equipment damage.

- Sequential control focuses on operational order and process efficiency, ensuring tasks progress in the correct sequence without workflow disruption.

Control Method

- Interlocking often involves mutually exclusive conditions: activation of one state inhibits others, and specific conditions must be satisfied to proceed.

- Sequential control relies on order-dependent execution; operations or devices proceed in a defined temporal or event sequence without necessarily being mutually exclusive.

Application Scenarios

- Interlocking is common in high-safety, complex operation systems such as power plants, petrochemical plants, and automated production lines.

- Sequential control is widely applied in production lines, logistics systems, network operations, and data processing, emphasizing continuity and efficiency.

3. Practical Examples

Chemical Reactor

- Interlocking: The pump cannot start if the reactor temperature is below set limits; the agitator cannot run if the cover is open.

- Sequential Control: Once the agitator starts, dosing pumps add reactants in sequence, ensuring the reaction follows the correct order.

Elevator Control System

- Interlocking: Prevents elevator movement when doors are not fully closed, ensuring passenger safety.

- Sequential Control: The elevator stops at floors in the correct sequence according to user calls, forming a floor call chain.

Automated Production Line

- Interlocking: Fault detection devices on conveyors immediately stop the system if abnormalities occur.

- Sequential Control: Each workstation triggers the next after completing its task, forming a production rhythm chain to maintain line efficiency.

4. Design and Implementation Recommendations

Choosing Interlock vs. Sequential Control Strategy

- Safety-critical operations should prioritize interlocking to prevent hazardous actions.

- Process flow and production efficiency operations should implement sequential control to maintain task continuity and smooth operation.

Hardware and Software Integration

- Hardware interlocks: Relays, limit switches, safety PLCs, mechanical barriers, suitable for high-reliability applications.

- Software interlocks/sequential control: Implemented via PLCs, DCS, or embedded control systems, enabling complex condition-based logic and ordered operation sequences.

Visualization and Monitoring

- Use HMI/SCADA interfaces to display interlock states and sequential flow in real time, helping operators quickly identify abnormal conditions.

- Combining interlock alarms with sequential status indicators allows rapid problem localization, improving safety and efficiency.

5. Conclusion

Interlocking and sequential control play complementary roles in industrial control, automation, and mechanical systems. Interlocking emphasizes safety and operational constraints to prevent errors or hazards, while sequential control focuses on process order and operational continuity to ensure efficiency. Understanding their differences and applying them appropriately improves overall system reliability, operational safety, and production efficiency.

In practical design, interlocks and sequential control often coexist: interlocks protect safety, and sequential control ensures smooth process flow. By combining hardware and software solutions, visualization, and well-designed strategies, systems can achieve a balance of safety and efficiency, operating reliably in complex industrial environments.