HAZOP, LOPA & SIL: Understanding Their Roles in Process Safety Management

In many industrial plants, discussions about safety often center on statements like: “We have alarms, interlocks, and safety valves.” However, a proper safety assessment is not merely about checking “whether these exist,” but about answering three critical questions:

- What could go wrong? (Scenario identification)

- Is the risk sufficiently low? (Risk evaluation)

- If not, how reliable must the protection be? (Reliability requirement)

In process safety, the three tools most frequently mentioned—and often confused—are HAZOP, LOPA, and SIL. Understanding them as a connected logic chain clarifies their roles:

- HAZOP identifies potential accident scenarios systematically.

- LOPA quantifies the risk of key scenarios in an auditable way.

- SIL sets the required reliability for safety instrumented functions (SIF) and safety instrumented systems (SIS).

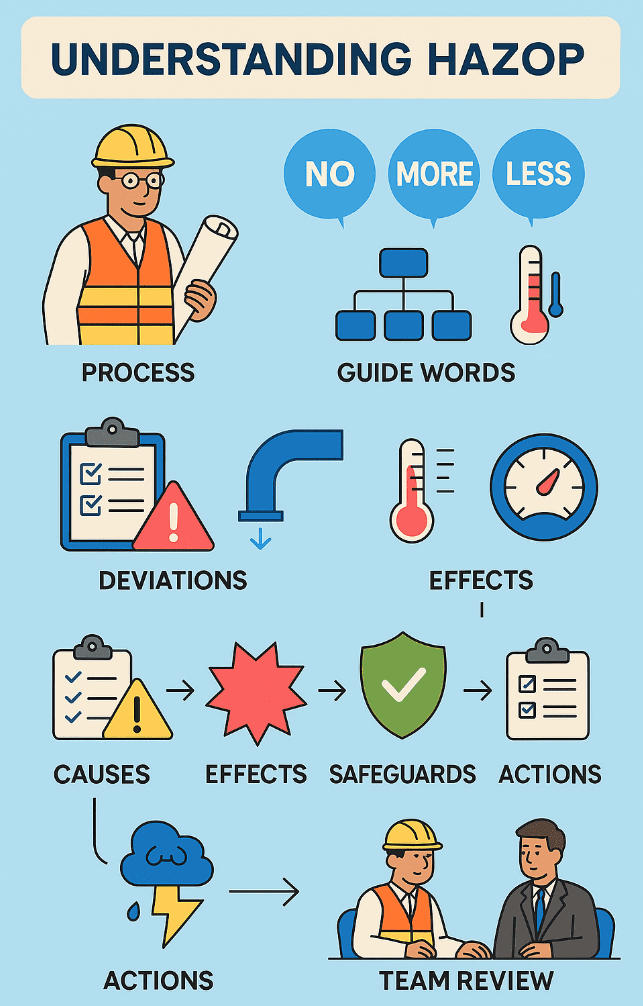

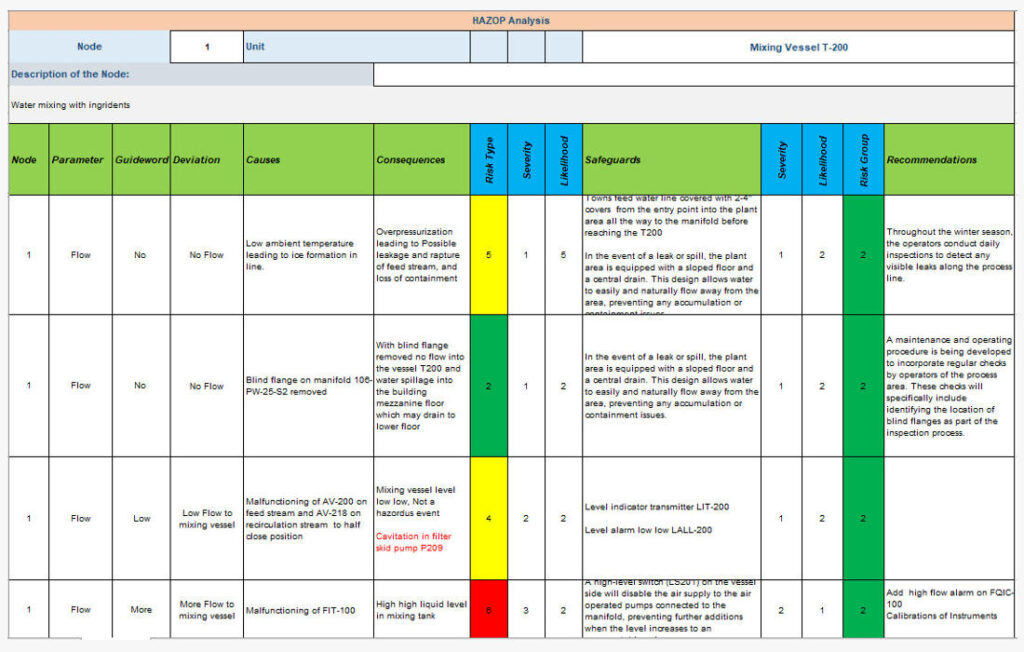

HAZOP

HAZOP (Hazard and Operability Study) is a discussion-based method aimed at systematically identifying process deviations and the potential hazards or operational issues they may cause. It does not assume that accidents will occur but rather asks:

If process parameters deviate from their intended design, what could happen?

A typical HAZOP study uses P&IDs and considers:

- Process parameters: flow, pressure, temperature, level, composition, etc.

- Guidewords: more, less, none, reverse, early, late, other, etc.

Through structured discussion, HAZOP identifies:

- Possible deviations

- Causes of deviations

- Consequences of deviations

- Existing safeguards

- Recommendations for additional measures

HAZOP serves as the starting point of process safety work, exposing potential risks. While it excels at “laying all problems on the table,” it does not answer whether the existing protections are sufficient—this is where LOPA comes in.

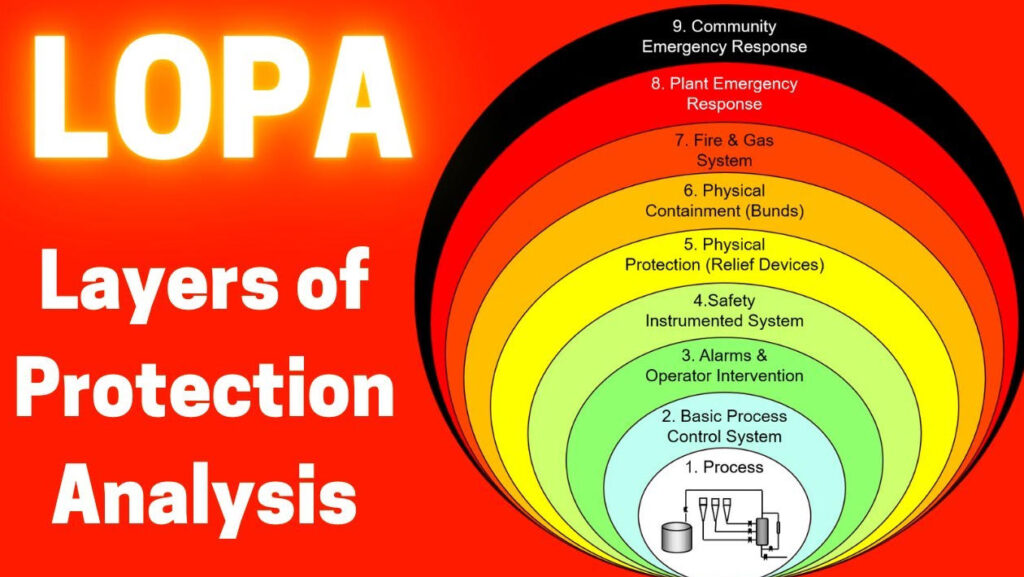

LOPA

LOPA (Layer of Protection Analysis) turns statements like “we have many protections” into auditable, quantified judgments. It evaluates key accident scenarios in a semi-quantitative manner: starting from the initiating event, it considers multiple independent protection layers (IPLs) to determine whether residual risk meets the company’s acceptable level. If not, LOPA identifies the gap—the additional risk reduction required.

A typical LOPA scenario is broken into four parts:

- Initiating event – e.g., equipment failure, human error, blockage, leak

- Independent protection layers (IPLs)

- Reliability of each layer – can it act effectively when needed?

- Residual risk – compared with corporate risk tolerance

The focus in LOPA is the IPL. For a measure to qualify as an IPL, it must satisfy engineering criteria:

- Independence: it should not share failure causes with the initiating event or other layers

- Effectiveness: it must reduce consequences or prevent the event

- Auditability: regular tests, maintenance, and documentation prove long-term reliability

- Response time: action must be timely relative to accident development

LOPA balances clarity and practicality: it does not aim to model everything in extreme detail but ensures that decisions—whether protections are sufficient, and if not, how much extra risk reduction is needed—are clear and auditable.

SIL

SIL (Safety Integrity Level), defined by IEC 61508 / IEC 61511, specifies reliability requirements for safety instrumented functions (SIFs). SIL answers:

Given the target risk reduction, how reliable must this SIF be?

A common misconception is that SIL applies to individual devices. In reality, SIL applies to an entire safety function chain: sensor → logic solver → final element, under specified operating conditions and demand modes.

- Low-demand mode: usually measured using PFDavg (Probability of Failure on Demand)

- High-demand / continuous mode: often measured using PFH (Probability of Failure per Hour)

SIL translates safety requirements into concrete engineering measures:

- System architecture and redundancy (e.g., 1oo1, 1oo2, 2oo3)

- Failure probability analysis and common cause considerations (diagnostics, bypass, β-factor)

- Proof test intervals, coverage, and maintenance strategy

- Change management and functional testing post-commissioning

This ensures that a documented SIL level (e.g., SIL2) is truly implemented in the field. Therefore, a “SIL-certified” valve or transmitter demonstrates component capability, but achieving the target SIL requires proper system design, verification, and long-term operation.

Functional Comparison: HAZOP, LOPA, SIL

| Dimension | HAZOP | LOPA | SIL |

|---|---|---|---|

| Primary purpose | Identify hazards and deviations | Assess whether risk is acceptable | Define required reliability of safety functions |

| Focus | What could happen | Is the risk low enough? | How reliable must the function be? |

| Analysis type | Qualitative | Semi-quantitative | Quantitative / standardized |

| Typical outputs | Deviation scenarios, recommendations | Risk evaluation, required risk reduction | SIL levels, design & implementation guidance |

| Engineering stage | Pre-design or early modification | Risk assessment phase | Design & implementation phase |

Example: Overpressure in a Reactor

- HAZOP identifies deviations: high/excessive pressure; explores causes such as blocked outlet, misclosed valve, runaway reaction, nitrogen blanket failure; lists consequences: overpressure → venting/rupture → toxic/flammable release; documents existing safeguards: control loops, alarms, PSV, interlocks.

- LOPA analyzes critical scenarios, mapping the chain: initiating event → protection layers → residual risk; identifies IPLs, calculates residual risk against criteria, and determines any missing risk reduction factor (RRF).

- SIL comes into play when additional SIF is required: converts the RRF gap into SIL requirements, guiding design, verification, testing, and maintenance.

Observation:

- Without HAZOP, potential scenarios may be missed

- Without LOPA, “sufficient protection” cannot be quantified

- Without SIL, required reliability cannot be translated into verifiable engineering measures

Summary

In practice, HAZOP, LOPA, and SIL are used sequentially and as needed:

- HAZOP: systematically identify potential hazard scenarios

- LOPA: evaluate whether existing safeguards meet acceptable risk

- SIL: when SIFs are required, specify reliability requirements and guide implementation

These tools are not competing; they complement each other to form a complete process safety analysis framework.