Selection of Wetted Materials for Industrial Instrumentation

In modern industrial production, the wetted parts of equipment are the core components of liquid flow control systems. Especially in chemical, pharmaceutical, food processing, and petroleum industries, the scientific selection of wetted materials directly affects production safety, efficiency, and cost-effectiveness. Choosing the right material not only extends equipment lifespan but also reduces failure rates and maintenance costs.

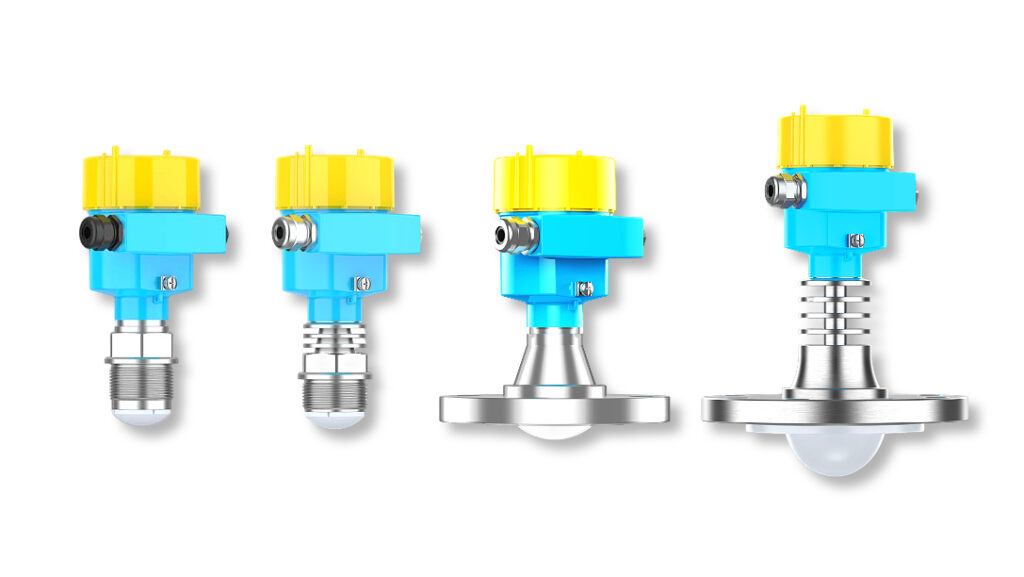

For instance, the Jiwei Ring-11 Hastelloy level switch can operate stably for extended periods in strong acid, strong alkaline, and high-temperature environments, ensuring reliable level monitoring. Meanwhile, PTFE and PFA radar level transmitters are suitable for extreme corrosive or high-temperature media, guaranteeing accurate and safe level measurement.

Basic Principles for Selecting Wetted Materials

The selection of wetted materials should comprehensively consider the characteristics of the liquid, operating temperature, pressure, and economic factors. Key principles include:

Corrosion Resistance

Liquids may contain strong acids, alkalis, or salts, making corrosion resistance critical. Hastelloy and PTFE materials perform exceptionally in acidic or alkaline environments, effectively preventing leaks and equipment damage.

Mechanical Strength

Wetted systems must withstand liquid pressure and flow impact. High-strength materials such as stainless steel, alloy steel, and titanium alloys ensure long-term operational stability.

Temperature Resistance

High temperatures reduce metal strength, while low temperatures may cause brittleness. High-temperature applications recommend 310 stainless steel, Inconel, or Hastelloy, while low-temperature environments can use low-temperature steel or special alloys.

Cost-Effectiveness

High-performance materials like titanium and Hastelloy are expensive. Where feasible, PTFE, PFA, or PP materials can optimize costs without compromising process requirements.

Environmental Adaptability

For outdoor or extreme environments, materials should resist UV, oxidation, and humidity to prevent aging.

Liquid Characteristics and Material Selection

The chemical properties, concentration, temperature, and pressure of the liquid directly influence wetted material selection:

Acidic Liquids

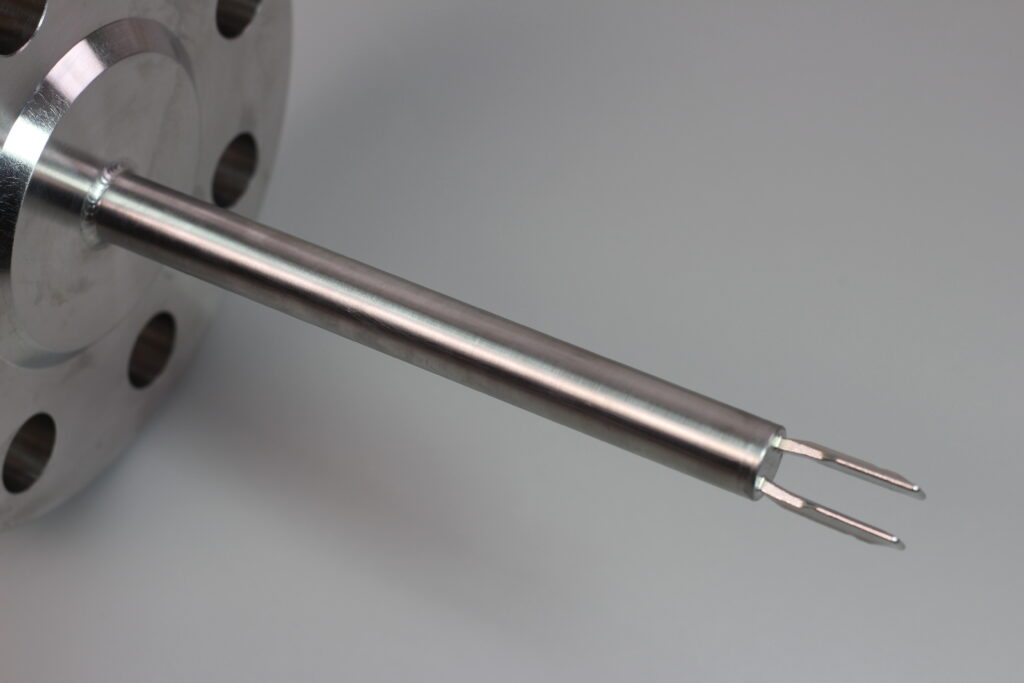

Strong acids such as sulfuric acid, hydrochloric acid, and hydrofluoric acid require Hastelloy, PTFE, or 316L stainless steel. Ring-11 level switches can operate reliably in such acidic media for long periods.

Alkaline Liquids

Strong alkalis like sodium hydroxide and ammonia water are compatible with PP, PE, or 304/316 stainless steel.

Organic Solvents

Benzene, alcohols, ketones, and similar solvents can aggressively attack metals. PTFE, PE, Hastelloy, or Inconel are recommended for radar level transmitters or piping systems to prevent corrosion.

Oils

Petroleum-based liquids such as crude oil, fuel, and lubricants have low corrosivity but require wear and pressure resistance. Carbon steel, aluminum alloys, or stainless steel are commonly used.

Water and Aqueous Solutions

Ordinary water can use carbon steel or stainless steel, while saline or highly corrosive aqueous solutions may require nickel-based alloys or Hastelloy.

Temperature and Pressure Effects on Wetted Materials

Temperature and pressure significantly affect material performance in wetted systems. Improper selection can lead to leaks, failure, or measurement inaccuracies.

High Temperature Effects

High temperatures can oxidize or soften metals, reducing mechanical strength.

- Ring-11 Hastelloy level switches operate stably in high-temperature acidic liquids.

- PTFE/PFA radar level transmitters can withstand liquid media up to 220°C while maintaining measurement accuracy.

Low Temperature Effects

Low temperatures may cause brittleness and material contraction.

- Low-temperature steel, Inconel, and special alloys maintain toughness, ensuring reliable Ring-11 level switch operation.

- PTFE/PFA materials retain chemical stability and mechanical flexibility even at low temperatures.

High Pressure Effects

High-pressure liquids increase the risk of material rupture and may interfere with level measurement.

- Hastelloy and high-strength stainless steel resist pressure impact, ensuring Ring-11 reliability.

- PTFE/PFA radar level transmitters with reinforced housings can measure high-pressure liquids stably.

Combined Temperature and Pressure Conditions

High-temperature, high-pressure conditions occur in reactors, steam systems, or hot acidic liquids.

- Jiwei Ring-11 level switches and PTFE/PFA JWrada radar level transmitters are industrially validated to operate reliably under complex temperature-pressure environments, compliant with IEC 61511/SIL2-SIL3 safety standards.

Recommended Wetted Materials

| Material | Key Properties | Typical Applications | Example Products |

|---|---|---|---|

| Stainless Steel 304/316 | Corrosion resistance, high strength | Acidic/alkaline liquids, oils, general aqueous solutions | Ring-11 level switch, PTFE/PFA JWrada radar level transmitter |

| Hastelloy | Exceptional corrosion resistance, high-temperature strength | Strong acids, chlorides, extreme temperatures | Ring-11 Hastelloy level switch |

| Titanium Alloy | High corrosion resistance, high temperature | Strong acids, hot liquids | Instrument wetted parts, level switches |

| PTFE / PFA | Extremely chemically stable | Strong acids, strong alkalis, organic solvents | PTFE/PFA JWrada radar level transmitter |

| PP / PE | Good chemical resistance, cost-effective | Alkaline liquids, low-pressure organic solvents | Pipe linings, light-duty level transmitters |

| Alloy Steel / Inconel | High temperature, high pressure, corrosion resistance | High-pressure, high-temperature reactors | Special radar level transmitters, level switches |

Conclusion

Scientific selection of wetted materials is a critical step in designing industrial liquid systems. By choosing appropriate materials such as stainless steel, Hastelloy, PTFE/PFA, or titanium alloys while considering temperature, pressure, liquid properties, and cost, industrial operators can significantly improve level monitoring safety and reliability.

In practical applications, Ring-11 Hastelloy level switches ensure stable level alarms in strong acid, strong alkali, and high-temperature environments. PTFE/PFA JWrada radar level transmitters provide continuous, accurate monitoring under extreme corrosion or high-temperature conditions. Through thoughtful material selection and design, industrial enterprises can achieve “safety, efficiency, and low maintenance” in liquid control systems.