Level Switch Output Selection Guide

In industrial settings, level switches are often regarded as “simple and single-function” instruments. However, in actual operation, many faults that seem unrelated to the probe itself are ultimately caused by improper selection of the output type. Examples include frequent signal fluctuations, PLC input anomalies, contact burn-out, and significantly reduced service life. These issues are not due to the detection principle itself but result from a mismatch between the output type, field conditions, and the control system.

Currently, the domestic market for level switches offers a variety of output types, including relay, transistor, thyristor (SCR), and two-wire outputs. While the options may seem abundant, in practice only one or two types are truly suitable for a given application. This article intentionally avoids excessive bullet-point lists and instead provides a systematic overview of the main output types from an engineering principle and practical application perspective, helping users make better choices during project selection.

1. Relay Output: The Most “Forgiving” Choice for Industrial Sites

Relay outputs are the most widely used type in domestic level switches and are also the most familiar and accepted by field engineers. Their core feature is that the internal detection circuit drives mechanical contacts to open or close, providing electrical isolation between input and output circuits.

In practice, the greatest advantage of relay outputs is their high load adaptability. They can switch AC or DC systems, whether it is a 24 V control voltage or 220 V/380 V power supply. This allows the level switch to directly drive contactor coils, intermediate relays, indicator lights, and audible/visual alarms without additional interface modules.

From a performance perspective, the response time of relay outputs is generally in the tens of milliseconds, which is sufficient for most level control and alarm applications. However, relay outputs are mechanical in nature, so contact wear inevitably affects their service life. Higher load currents and more frequent operations reduce the contact lifespan.

Therefore, in applications with low switching frequency and the need to directly drive high-power loads, such as high/low-level alarms, safety interlocks, or pump and valve control, relay outputs remain the most reliable and convenient choice.

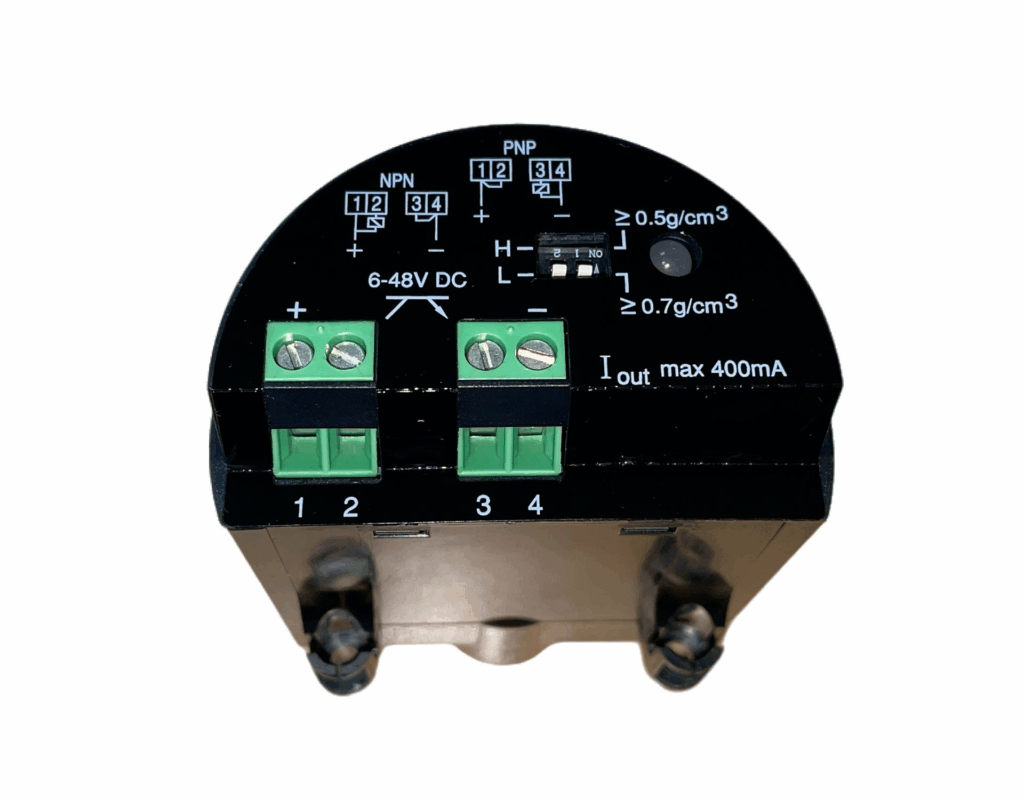

2. Transistor Output: Designed for High-Frequency and Long-Life Operation

Transistor outputs are typical contactless electronic outputs, where conduction is achieved through semiconductor devices, eliminating the mechanical contact structure of relays. Common forms include NPN and PNP outputs, primarily used in DC control systems.

Compared with relays, the most notable feature of transistor outputs is their extremely fast response time, typically in milliseconds or sub-milliseconds. This makes them ideal for high-frequency switching or applications with strict timing requirements. Additionally, without mechanical wear, transistor outputs have a theoretical service life far exceeding that of relays, providing advantages in long-term continuous operation.

However, transistor outputs have limitations. They can only drive DC loads and have strict voltage and polarity requirements. Their output current capacity is limited, usually suitable only for small loads. As a result, transistor outputs often serve primarily as signal transmission outputs rather than directly driving actuators.

In practice, transistor outputs are often connected directly to PLC digital input modules or used to drive solid-state relays and servo controllers. If high-frequency operation must also drive high-power loads, intermediate relays or solid-state relays are typically added for signal amplification.

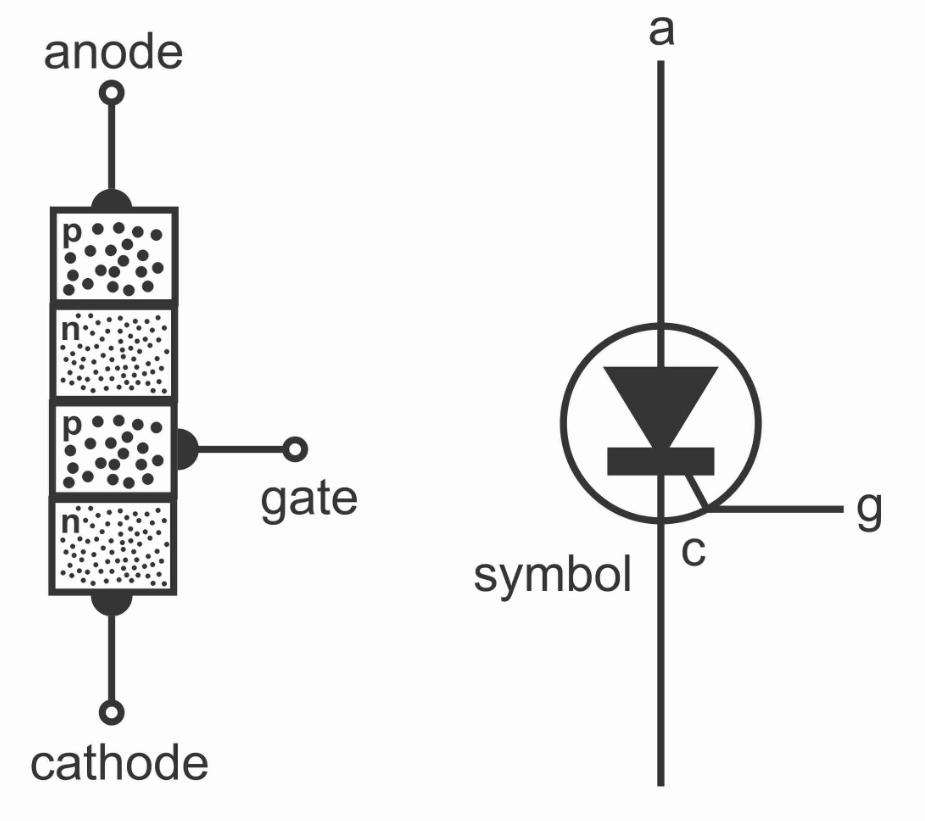

3. Thyristor Output (SCR): Electronic Switching for AC Systems

Thyristor outputs, also called SCR outputs, are electronic switching types specifically designed for AC circuits. Conduction is triggered by a control signal, while turn-off relies on the natural zero-crossing of AC current, making them unsuitable for DC systems.

In level switch applications, thyristor outputs sit between relay and transistor outputs. On one hand, they avoid mechanical contact wear, offering longer service life; on the other hand, their response speed is faster than relays but slightly slower than transistors.

It should be noted that although thyristor outputs can handle relatively high AC voltages, their output current capacity is usually limited. They are mainly used for signal-level or medium-power load control, such as directly driving contactor coils. In domestic applications, this output type is relatively specialized, often chosen for AC high-frequency switching scenarios.

4. Two-Wire Output: A Specialized Choice for Intrinsically Safe Applications

Two-wire outputs differ from traditional switch outputs, operating more like a current loop signal. The level switch uses the same pair of wires for both power supply and signal transmission, with changes in current indicating the detected level.

This output type is primarily used in hazardous areas with intrinsically safe requirements, such as petroleum and chemical industries. In domestic applications, two-wire solutions are less common due to stricter system design, power supply, and load matching requirements. However, they remain indispensable in certain explosion-proof or intrinsically safe applications.

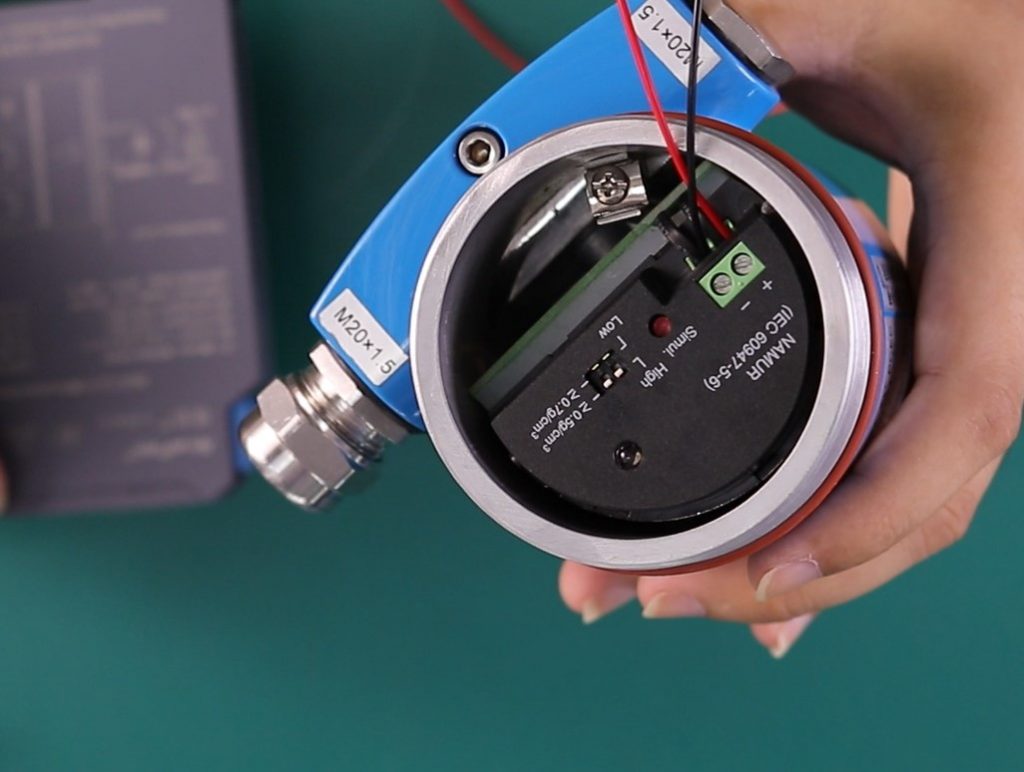

5. NAMUR Output: Standardized Signal for Hazardous and Intrinsically Safe Areas

NAMUR outputs are a standardized type of low-current signal commonly used in chemical, pharmaceutical, and other hazardous environments. The term “NAMUR” originates from the German industry association that defines the specifications for these sensors. Typically, NAMUR devices operate in the 8–10 mA current range, signaling a high or low state without directly driving external loads.

The primary advantage of NAMUR outputs lies in intrinsic safety compliance. Because the signal current is low and standardized, it can be safely connected to intrinsically safe amplifiers or controllers in explosive atmospheres, minimizing the risk of sparking or overheating. In practice, a NAMUR level switch is not used to directly switch loads but provides a reliable signal to interface with control systems designed for hazardous areas.

NAMUR outputs are especially suitable for direct integration with PLCs, safety controllers, or signal isolators in intrinsically safe circuits, making them an essential choice when compliance with IECEx, ATEX, or other safety standards is required. This output type complements the more conventional relay, transistor, and SCR outputs in environments where safety and standardization are critical.

6. Key Considerations for Engineering Selection

Overall, there is no single “best” output type for level switches. The key is whether the output type matches the field conditions and control system requirements. Relay outputs offer broad applicability and high load capacity, suitable for conventional industrial sites. Transistor outputs excel in high-frequency operation and long-life applications. Thyristor and two-wire outputs are designed for specialized system conditions.

When selecting an output type, engineers should first clarify: Is the control system AC or DC? What is the required load capacity? Is the level signal switching frequency high? Are there explosion-proof or intrinsic safety requirements?

Only when these conditions are clearly understood can the level switch output type deliver its full reliability and engineering value.