Nickel Sulfate Pipeline Level Monitoring: Reliable Solutions with Jiwei Fork Level Switch

Nickel sulfate solution (NiSO₄ Solution) is a common base material in industries such as new energy battery precursors, nickel salt chemicals, and electroplating. While it appears as a green transparent liquid, it poses numerous engineering challenges in pipeline transport and level monitoring. Nickel sulfate exhibits certain viscosity, generates bubbles, may crystallize and adhere to surfaces, and is corrosive. These factors combined make point-level detection in pipelines a major concern for many engineers. In conditions where multiple pipelines intersect, pumps frequently start and stop, and flow is unstable, the risk of false alarms or measurement failure increases significantly, posing potential threats to production safety and equipment lifespan.

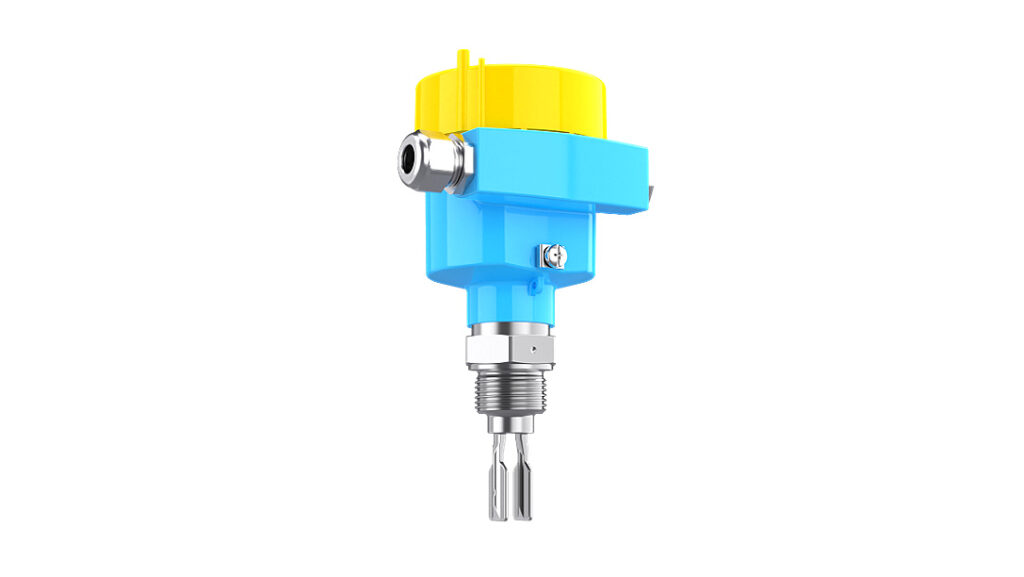

Jiwei Fork Level Switches, developed by Shenzhen Jiwei Automations Ltd., have been extensively validated in such conditions and proven to be stable, maintenance-free, and engineering-friendly solutions. Even VEGA’s headquarters in Germany has procured Jiwei products, indicating that Jiwei has reached the reliability and quality level of major international brands. Compared to traditional float, rotary paddle, or electrode-type level switches, Jiwei Fork Level Switches are more adaptable to complex chemical media and confined spaces, providing reliable protection for industrial operations.

1. Medium Characteristics and Engineering Challenges of Nickel Sulfate Solution

Although nickel sulfate solution seems ordinary, it contains multiple hidden challenges for level monitoring. The first challenge is flowability and viscosity. Under normal operating temperatures, the solution exhibits moderate flowability, with viscosity slightly higher than water. In high-concentration or low-temperature environments, flowability further decreases, affecting instrument response speed. Traditional float or rotary paddle instruments can lag, resulting in pump dry-run or delayed alarms.

The second challenge is corrosion. Nickel sulfate solution can corrode carbon steel and ordinary stainless steel, with higher temperatures and concentrations accelerating corrosion rates. Materials such as 316L stainless steel or Hastelloy are more suitable for long-term operation, ensuring probes function reliably without chemical degradation.

Third, bubble formation and flow disturbances are common. Electrolysis, pump transport, and stirring frequently generate bubbles, which can linger near level switch sensors, causing signal attenuation or frequency changes. For conventional switches, such disturbances may trigger false alarms or delayed responses. Jiwei Fork Level Switches, with their high natural frequency design, maintain stable detection even in the presence of bubbles.

Lastly, crystallization and adhesion can occur. High concentrations or low temperatures may cause nickel sulfate to crystallize, forming layers on the probe surface that affect sensitivity. Contact-type switches can fail under such conditions, but Jiwei Fork Level Switches maintain accurate measurement due to their vibration-based detection principle, even with minor deposits.

2. Field Challenges of Level Measurement

In real-world applications, level measurement faces challenges beyond the medium itself. Multiple intersecting pipelines, frequent pump starts and stops, variations in pipe diameter, and turbulence at bends can all affect probe readings. Key points such as tank outlets, pump inlets, branch lines, return lines, and CIP cleaning sections require precise level monitoring to prevent pump dry-run, pipeline blockages, and material overflow. Level switches must respond quickly and maintain long-term stability.

Process fluctuations and environmental changes also pose challenges. Intermittent flow, temperature variations, steam interference, pipe vibration, and external noise can affect traditional instruments. Electrode-type switches may fail due to medium conductivity, polarization, or passivation, while float and rotary paddle switches are prone to adhesion or mechanical jamming. This underscores the need for a solution that can handle complex media, respond rapidly, and remain reliable with minimal maintenance.

3. Technical Advantages of Jiwei Fork Level Switch

Jiwei Fork Level Switches show significant advantages in complex pipeline conditions. Their core strength lies in vibration-based detection, which does not rely on medium conductivity or other properties. They are unaffected by viscosity, temperature, or electrical characteristics, providing stable detection of liquid presence. The high natural frequency design ensures that bubbles, minor deposits, or turbulence do not interfere with signals. Even in pipeline segments with frequent pump starts and fluctuating flow, the switch provides rapid and reliable feedback.

Installation flexibility is another advantage. Jiwei offers multiple connection types, including clamp, threaded, and flange, as well as short probe options for tight spaces. Materials range from 316L stainless steel and Hastelloy to corrosion-resistant coatings, covering diverse concentration, temperature, and corrosive conditions, ensuring long-term maintenance-free operation.

The response speed of Jiwei Fork Level Switches is also excellent. They detect liquid presence immediately, supporting pump protection and low-level monitoring. In continuous transport, branch lines, and return pipelines, the switch accurately detects liquid, preventing dry-run conditions and reducing material waste.

4. Practical Case Studies

In a nickel sulfate transport system at a new energy battery plant in Shandong, traditional float switches frequently jammed or triggered false alarms, causing pump dry-run and production delays. After installing Jiwei Fork Level Switches, continuous, stable, and fast level detection was achieved. Key protection functions—including pump inlet monitoring, low-level alarms, and intermittent transport monitoring—were reliably implemented. Pump dry-run incidents dropped to zero, maintenance frequency decreased, and production efficiency improved noticeably.

In a heated jacket residue oil tank, where liquid temperatures reached 70–90°C and viscosity was high, traditional instruments struggled. Jiwei Fork Level Switches provided real-time feedback of liquid levels via stable vibration detection, supporting automatic heating and pump control, significantly reducing manual inspections. Their vibration-based measurement principle minimized maintenance costs, ensuring long-term reliable operation.

In a desalter tank, where oil-water emulsions were prominent, conventional instruments failed to accurately identify the oil-water interface. Jiwei Fork Level Switches accurately distinguished the interface, stabilizing measurements, improving desalting efficiency, and ensuring downstream distillation tower stability. Standardizing multiple production lines with Jiwei solutions simplified maintenance and enhanced process safety and continuity.

5. Practical Value of Level Measurement

Accurate level measurement ensures safety and enhances production efficiency. Real-time monitoring prevents pump dry-run, pipeline blockages, and material overflow, reducing risks. Continuous and stable data can be integrated into automation systems, decreasing manual intervention and increasing plant utilization. The non-contact or vibration-based design reduces wear and adhesion issues, lowering downtime and maintenance costs.

High-precision measurement supports environmental compliance, including overfill protection, leakage prevention, and VOC control. Accurate inventory data aids supply chain planning and resource allocation, enabling cost optimization and efficient operations. Enterprises can simultaneously improve safety, environmental compliance, and operational efficiency.

6. Conclusion

Nickel sulfate pipeline level monitoring appears simple but involves hidden challenges, including bubbles, adhesion, corrosion, crystallization, and limited installation space. Many conventional instruments may experience false alarms, delayed responses, or failure in such conditions.

Jiwei Fork Level Switches, with their anti-bubble, anti-adhesion, selectable materials, flexible installation, and rapid response, provide a reliable solution for these challenging applications.

By deploying Jiwei Fork Level Switches, enterprises achieve continuous, stable, drift-free detection, precise monitoring of complex media, and seamless integration with automation systems, enhancing production safety and equipment reliability. For organizations seeking high safety margins, low maintenance costs, and accurate measurement, Jiwei Fork Level Switches are an indispensable tool for nickel sulfate pipeline level monitoring.